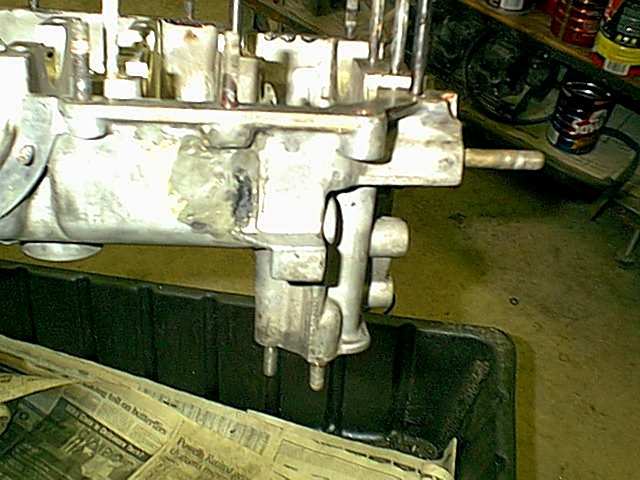

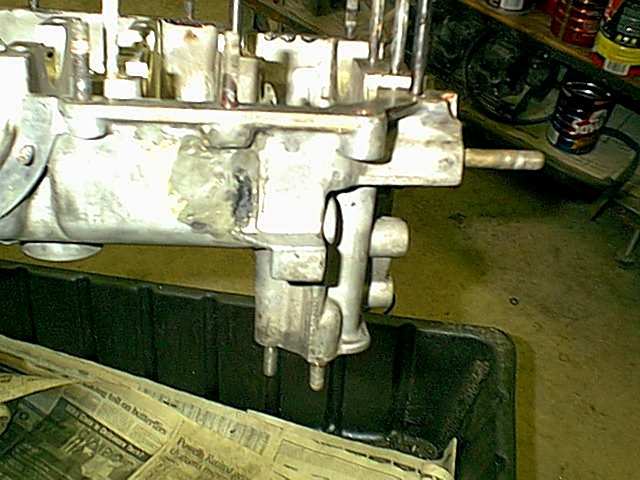

What a mess! God knows where that came from.

Hole in the case. Fixed poorly sometime in the past. I

put

a smooth layer of Epoxy over the inside.

What a mess! God knows where that came from.

I left the existing Epoxy patch on the outside alone.

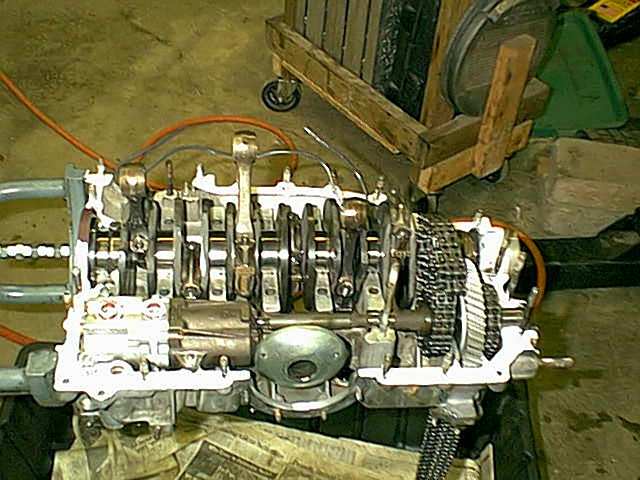

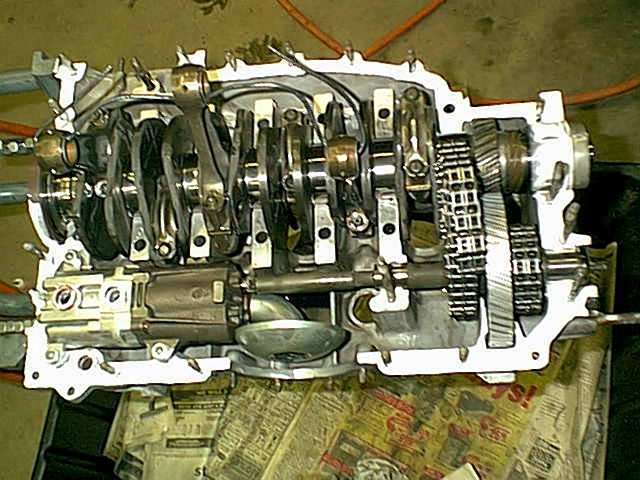

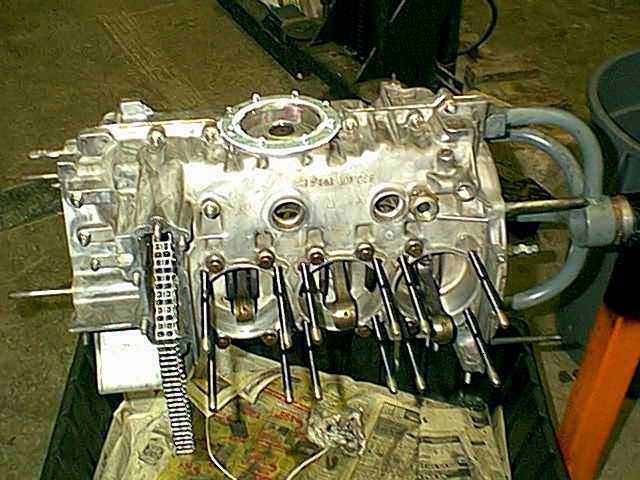

Here are the new 993 Studs freshly installed with red loctite.

Now install the crank, which is already built with fresh bearings,

reconditioned

rods, new 993 nuts and 964 bolts

The rods will be torqued to the latest specification after the case

is assembled.

Apply Dow Corning 730 anaerobic sealant to the case halves.

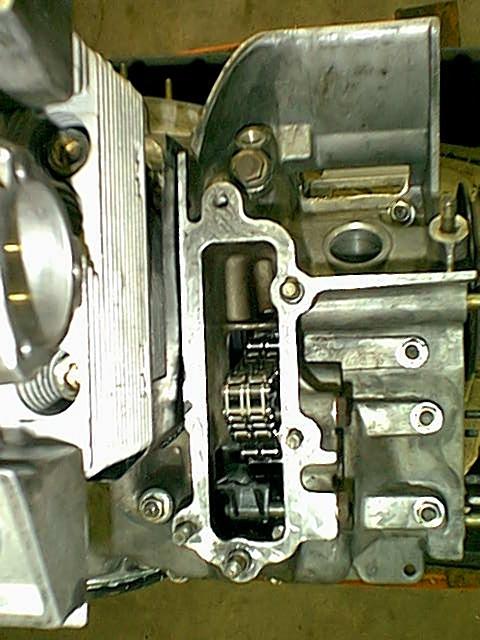

After installing case through bolts and o-rings and torquing the filter and screen are installed.

Now the rods are torqued, 15 NM + 2 times 90

degrees.

Not int he picture, but it's

interesting to see how the torque plateaus at about 48 ft-lbs about

10 degrees into

the last stage as the bolts are in stretch- plastic yield mode.

Sensors and other items installed.

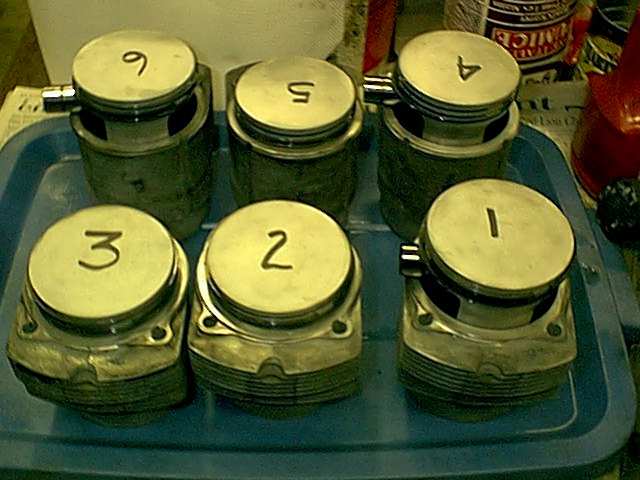

Pistons are then decorbonized, then recleaned and new rings

installed.

They are numbered with BIG numbers so they do not get mixed up during

reassembly.

Cylinder mating surfaces have been freshly "faced", i.e. ground

square

and even

so that they can properly seal to the underside of the head without

a gasket.

Now the pistons are installed onto the rods and the wrist-pin clips

installed,

and the "jugs" are slid over the pistons.

A special piston ring compressor is used that can be removed from

under the piston and around the connecting rod.

As easy as 3-2-1!

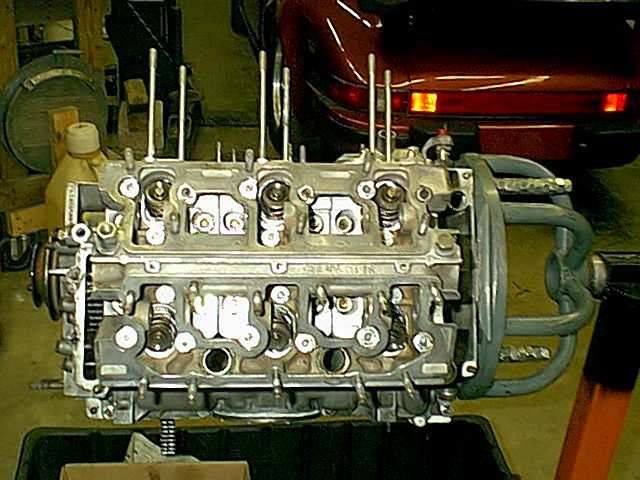

Now install the already assembled (off camera) cam-tower and head

assembly

and torque the heads per spec (10MN and 32NM in 2 steps)

Now for the right bank (4-6)

Here it is from the rear. Sheet metal was bead blasted repainted and baked.

From the front.....

Nice shiny new head bolts and washers!

time the cams

Someone spray-painted the chain covers with black paint (and grease?). This is a before and after bead blasting.

Install and adjust all the rockers and then chain and cam covers....

And a few hours later....install the sheet metal, shroud, fan,

distributor,

etc. and engine mount.

BLEEECH!

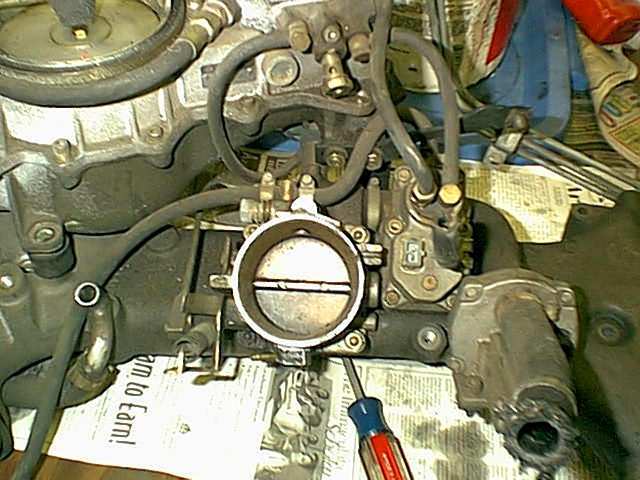

A really dirty intake assembly.

A much cleaner intake assembly.

Now install the intake manifold, CIS the corssmember, and more sheetmetal.

Now route some nice new Magnecore wires to replace the buggered up stock units...

Looks like th air cleaner has to go....and I'll recoat the intercooler neck.

Nice to work on a motor and not get dirty!