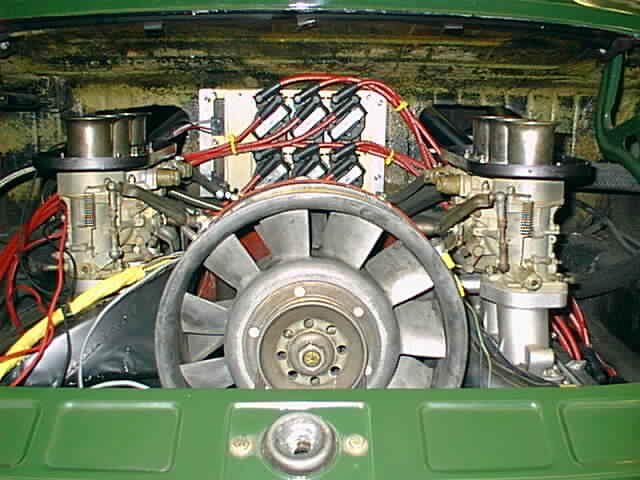

Specs: Twin plg 10.5:1 comprssion with happy cams and webers.

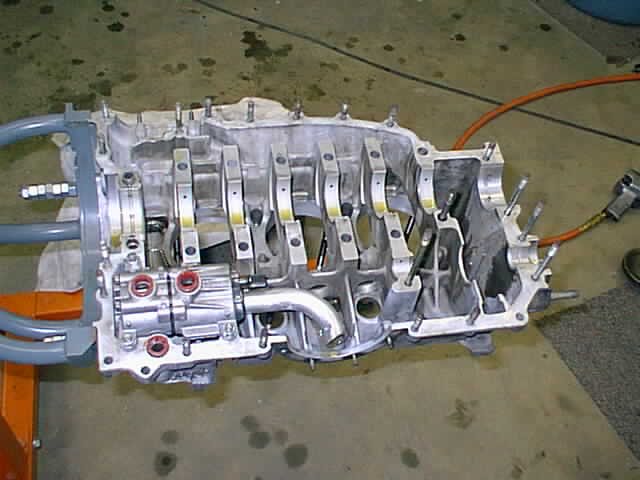

Make sure the case is VERY clean and the bearings are installed and

lubricated. New 993 studs were installed int he case and

the oil pump was cleaned and checked. New intermediate shaft bearings

are also installed.

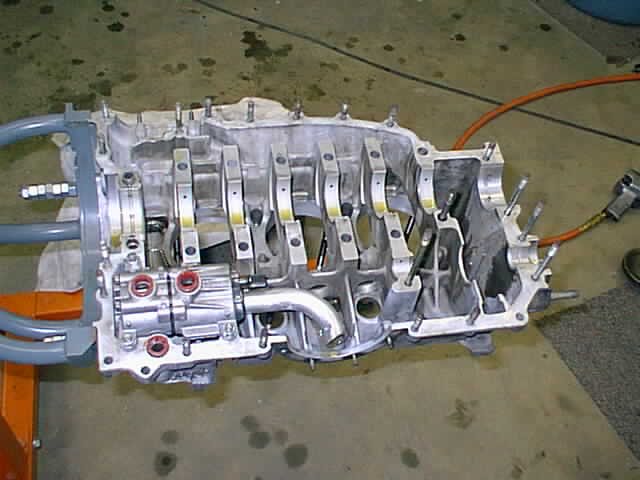

Rods were balanced to within 0.10 grams, polished and installed using raceware studs.

Now the crank and rods are carefuly installed....Don;t forget the intermediate shaft and chains!

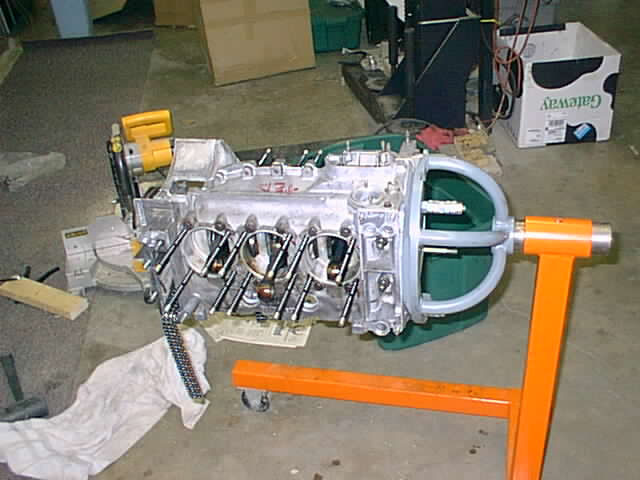

It's a good idea to lay out the piston/cylender assemblies.

Protect the rings and piston from the threads on the studs. No nicks are acceptable.

Install the piston on the rod, then use the special piston ring compressor...

Remove the compressor and.....

Blip! It's done. Slide the cylender into the case, being

sure not to damage the copper gasket.

Next....use a pylender holding nut so you can turn the crank without moving the cylender

Repeat

Ando so it goes.

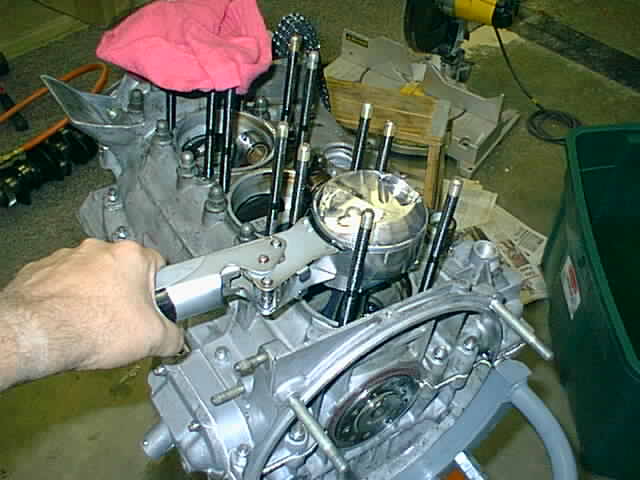

Now, sicne we are using high lift cams and high dome pistons it's a good idea to "clay" the cylenders.

We did this on #1, You need to assemble the head/cam tower (see below)

time the came properly, and turn the engine through 2 complete revolutions,

then dissasemble.

You them cut the clay with a razor (without nicking the piston) and measure thickness.

In this case I assembled the heads to the cam towers since I had to clay the cylenders.

Then we assemble and time the cams using a dial indicator.

We skipped a few steps....then installed the motor complete with twin-plug

ignition on a special mounting braket.

Top is top, bottom is bottom. Makes sense to me!

Note the yellow fan strap and wires. John Deere?

Pretty sweet.

Next we installed a nose mounted Racer's Group 60 row cooler.